In the realm of metal fabrication, particularly with stainless steel, cold processing plays a pivotal role in achieving the desired shapes and mechanical properties for a wide range of applications. This process involves the plastic deformation of stainless steel at temperatures below its recrystallization point, typically around half of the metal’s melting temperature. Cold working, or cold processing, not only allows for precise dimensional control but also significantly enhances the material’s strength and consistency.

This introduction to cold working in stainless steel will provide a foundation for understanding how this process benefits various industries, from medical to consumer goods, and the unique properties it imparts to the metal.

Hot Work vs. Cold Processing in Stainless Steel Fabrication

The distinction between hot work and cold working in stainless steel is primarily governed by the temperature at which the metal is processed. However, these two techniques differ in several other critical aspects that influence their applications and outcomes.

Recrystallization and Metal Forming

1. Recrystallization is a key concept in metallurgy, marking the point at which metal atoms reorganize into new crystal structures. Each metal, including stainless steel, has a unique recrystallization temperature, defining whether the process is considered hot or cold.

2. Hot Work occurs above this recrystallization temperature, leading to no strain hardening and ensuring high ductility. However, it requires significant heat energy, impacting the longevity of metallurgical tools and indirectly raising costs.

3. Cold Processing, performed below the recrystallization temperature, requires greater force to shape the metal but results in smoother surfaces and more controlled mechanical properties.

Understanding these differences is crucial for selecting the most suitable method for stainless steel fabrication, depending on the desired properties and application of the final product.

Exploring Types of Cold Processing in Stainless Steel

Cold processing of stainless steel encompasses a variety of methods, each tailored to specific requirements and outcomes. The choice of process depends largely on the intended use and desired properties of the final product. Here, we delve into the main types of cold working processes used in stainless steel fabrication:

1. Squeezing Methods

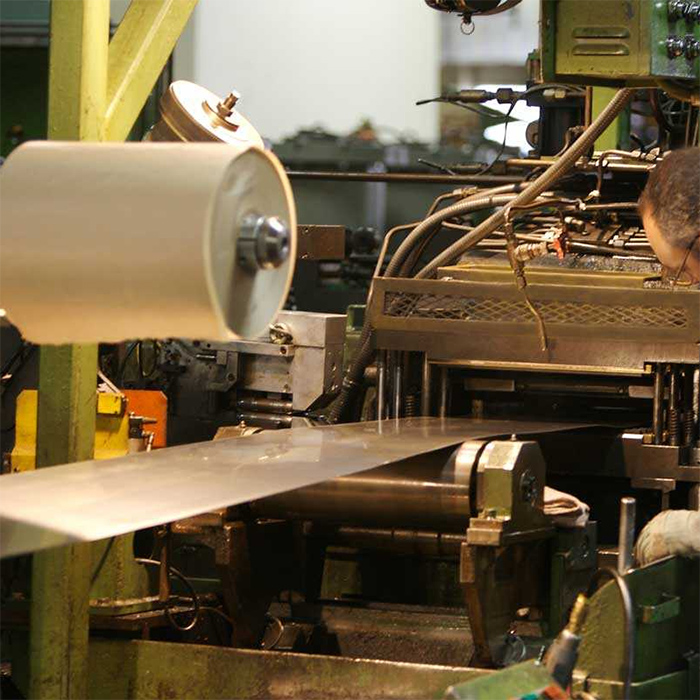

Cold Rolling: A prevalent method where stainless steel is passed through rollers under pressure, resulting in products with smooth surfaces and enhanced strength due to strain hardening.

Cold Forging and Coining: These involve placing metal between dies and applying high pressure to shape it, offering precision and strength.

Extrusion: This process forces stainless steel through a die, shaping it into specific cross-sections.

2. Bending Techniques

Techniques like roll forming and tube bending involve shaping long strips or tubes of stainless steel through sets of rolls, achieving desired bends and cross-section profiles.

3. Shearing Processes

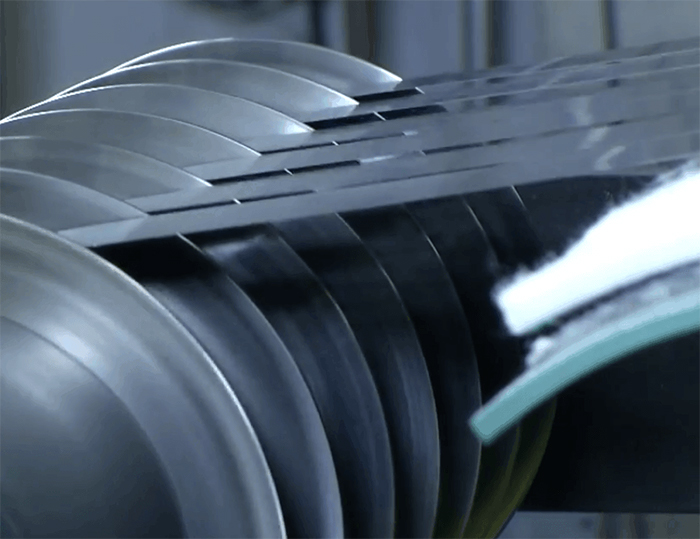

Common methods include slitting, where stainless steel sheets are cut into narrower strips, offering uniformity and precision in dimensions.

4. Drawing Practices

In cold drawing, stainless steel is pulled through dies to extend the material without cracking, often used in creating complex shapes like medical device components.

5. Precision Stamping

A complex process that may combine various techniques like punching, blanking, and bending. It’s ideal for products where tight tolerances are required, such as in aerospace components.

Each of these cold processing techniques imparts distinct characteristics to stainless steel, making it adaptable to a wide array of applications across various industries.

Applications and Advantages of Cold Processing in Stainless Steel

Cold processing is not just a method of shaping stainless steel but a way to enhance its properties for diverse applications. Let’s explore the various applications and the benefits of this process:

Applications of Cold Working in Stainless Steel

Industrial and Consumer Goods: From intricate components in vehicles and aircraft to consumer products, cold processing is vital for achieving precise shapes and robustness.

Medical Devices: Techniques like precision stamping are crucial for manufacturing critical medical devices, including pacemaker components and hypodermic needles.

Complex Shapes: Many specialized products require the precision and strength that only cold working can provide, making it a preferred choice in manufacturing complex shapes.

Benefits of Cold Processing

Increased Strength: Cold working enhances the tensile strength of stainless steel, making it more robust and suitable for demanding applications.

Improved Surface Finish: Cold-processed steel typically has a smoother surface, ideal for consumer goods where aesthetics are important.

Efficiency and Cost-Effectiveness: Since cold working doesn’t involve metal waste and extensive heating, it is often more economical and environmentally friendly compared to hot working.

Cold working processes are indispensable in stainless steel fabrication, offering the dual advantages of functional excellence and economic efficiency. This makes it a key process in industries where both strength and precision are paramount.

Materials Suitable for Cold Processing in Stainless Steel

While cold processing is a versatile technique in metal fabrication, it’s important to understand its applicability to different types of materials. Here we discuss the suitability of various metals for cold working, particularly focusing on stainless steel:

Metals Ideal for Cold Working

Stainless Steel and Its Alloys: Being highly adaptable, stainless steel is often the prime choice for cold processing, suitable for a range of applications from industrial components to consumer products.

Nickel-Based Alloys and Tool Steels: These materials are also well-suited for cold working, offering strength and durability in finished products.

Other Metals: Aluminium, copper, and certain grades of titanium and cobalt can also undergo cold processing, each offering unique properties to the finished product.

Limitations in Cold Working Certain Metals

Size Limitations: Generally, cold working is more suited for smaller-sized metal pieces. Larger pieces require significant force, making them less ideal for this process.

Incompatibility with Certain Metals: Some metals, like carbon steel and specific alloy steels, do not respond well to cold working at room temperature. Also, certain metals like copper, while cold workable, may become brittle over time due to the process.

Understanding these material considerations is crucial in choosing the right cold processing method for your stainless steel fabrication needs, ensuring optimal outcomes in both performance and cost.

Conclusion: Embracing the Power of Cold Processing in Stainless Steel Fabrication

In the intricate world of stainless steel fabrication, cold processing stands out as a key technique that significantly enhances the metal’s properties. Throughout this exploration, we’ve seen how cold working, or cold processing, not only shapes stainless steel into desired forms but also strengthens and refines it for a multitude of applications.

From creating robust components for aerospace and automotive industries to precision parts for medical devices, cold processing’s versatility is unmatched. Its ability to improve material strength and surface finish, combined with its cost-effectiveness and efficiency, makes it an invaluable process in the stainless steel manufacturing sector.

At the heart of achieving these superior qualities is understanding the right materials and processes for specific applications. By leveraging the benefits of cold processing in stainless steel, manufacturers can meet the demanding requirements of various industries, ensuring both quality and reliability in their products.

We hope this insight into cold processing has provided a deeper appreciation of its role in stainless steel fabrication and the myriad ways it can enhance the performance and aesthetics of metal products.

Post time: Dec-11-2023