Welcome to our exploration of stainless steel slit coil, a crucial component in diverse industrial applications. This specialized product, known for its versatility and durability, plays a key role in various manufacturing processes. Understanding stainless steel slit coil is essential for industries seeking efficient, high-quality materials for their products. Join us as we delve into the intricacies of stainless steel slit coil, uncovering its production process, applications, benefits, and selection criteria. Our goal is to provide a comprehensive guide that illuminates the importance and utility of this indispensable material.

Understanding Stainless Steel Coil Slitting

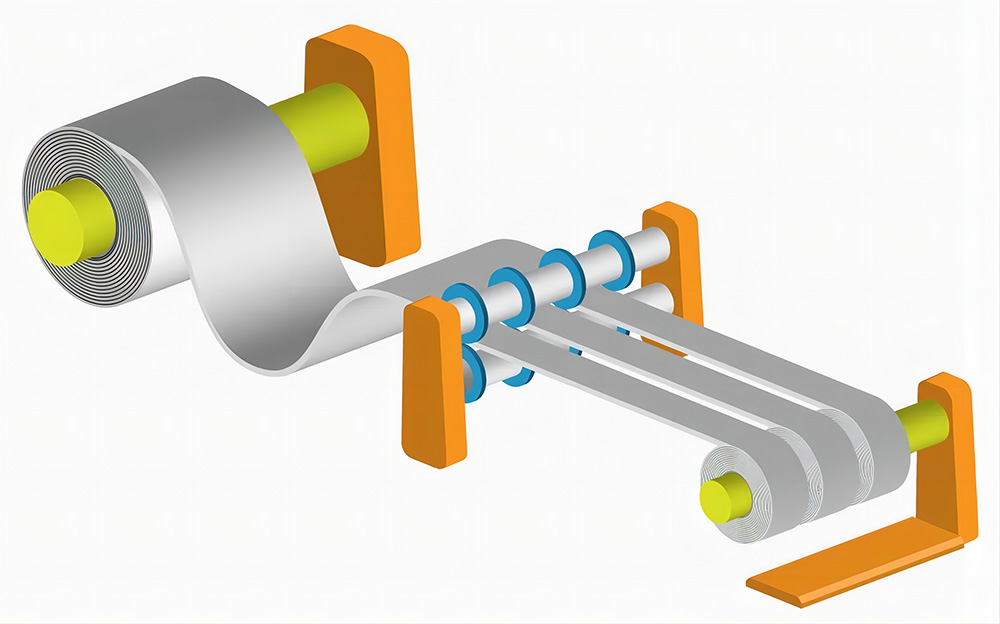

The process of slitting stainless steel coils is both an art and a science, crucial for producing strips that meet exacting standards. It begins with large, master coils of stainless steel. These coils are then carefully fed through a slitter – a machine equipped with sharp rotary blades. The precision in this process lies in the blade’s setup, calibrated to cut the coil into specified widths without compromising the metal’s integrity.

As passes through the slitter, the blades slice it into narrower bands, a process that demands precision to maintain uniformity across each strip. The intricacies of the blade adjustment, the tension of the coil, and the speed of slitting play critical roles in ensuring the quality of the final product. This methodical approach results in stainless steel slit coils that are tailored for specific applications, maintaining a balance between strength and flexibility. The art of coil slitting not only requires technical expertise but also a deep understanding of the material properties to achieve the desired outcome.

Applications of Stainless Steel Slit Coil

Stainless steel slit coils are utilized in a multitude of applications, thanks to their versatility and durability. Their use spans various industries:

Automotive Industry: Here, slit coils are used for parts requiring strength and corrosion resistance.

Construction: They play a role in building materials, offering both aesthetic appeal and structural integrity.

Electronics: In this sector, slit coils are essential in components that demand precise measurements and reliability.

Medical Equipment: Their use in medical devices highlights the material’s safety and hygiene properties.

This wide range of applications demonstrates the adaptability of stainless steel slit coils, making them a preferred choice for diverse industry needs.

Advantages of Using Stainless Steel Slit Coils

The use of stainless steel slit coils offers several key advantages:

Precision and Flexibility: They allow for precise control over dimensions, essential in applications where exact measurements are crucial.

Strength and Durability: These coils provide exceptional strength and longevity, making them suitable for demanding environments.

Efficiency in Production: Slit coils facilitate efficient manufacturing processes, reducing waste and saving time.

Aesthetic Appeal: They offer a sleek and modern look, enhancing the visual aspect of the final product.

These benefits make stainless steel slit coils a valuable material in various sectors, aligning with the growing demand for high-quality, durable, and aesthetically pleasing materials.

Types of Stainless Steel Slit Coil

Stainless steel slit coils come in various types, each suited to different applications:

Austenitic Stainless Steel: Known for its corrosion resistance and weldability, ideal for harsh environments.

Ferritic Stainless Steel: Offers better engineering properties and magnetic qualities, used in consumer appliances.

Martensitic Stainless Steel: Characterized by higher strength and hardness, suitable for cutlery and surgical instruments.

Duplex Stainless Steel: Combines the qualities of austenitic and ferritic, providing enhanced strength and corrosion resistance.

Each type offers unique properties, making the selection process critical to match the specific requirements of your project.

Choosing the Right Stainless Steel Slit Coil

Selecting the appropriate stainless steel slit coil involves several considerations:

Application Needs: Understand the specific requirements of your project, including environmental conditions and mechanical demands.

Material Type: Choose the type of stainless steel that aligns with your project’s requirements for strength, corrosion resistance, and aesthetic appeal.

Thickness and Width: Determine the suitable thickness and width of the coil, which are crucial for the functionality and efficiency of your application.

Expert guidance can be invaluable in this selection process, ensuring you make the best choice for your unique application.

Conclusion

In wrapping up our comprehensive guide on stainless steel slit coils, it’s clear that this material is indispensable across various industries for its durability, precision, and versatility. Whether you’re dealing with construction, automotive, medical, or other industrial applications, selecting the right stainless steel slit coil is crucial. We’re here to assist you in navigating these choices, ensuring you find the perfect fit for your specific needs. Reach out to us for expert advice and to explore our range of high-quality stainless steel slit coils, tailored to elevate your next project. Let’s collaborate to bring your vision to fruition.

Post time: Dec-18-2023