301 Stainless Steel Coil

What is 301 Stainless Steel Coil?

Type 301 is an austenitic stainless steel, alloyed with chromium and nickel, known for its versatility in both annealed and cold worked conditions. When annealed, it provides exceptional stretch formability, surpassing all other stainless steels. As it undergoes cold working, it transforms to exhibit the highest strength levels found within the 300 series stainless steels. Initially non-magnetic, 301 becomes magnetic after cold working, reflecting its transformative properties.

Although 301 stainless steel is corrosion-resistant across various environments, its anti-corrosive capabilities slightly trail behind those of the 304/304L stainless steel variants, primarily due to its vulnerability to carbide precipitation during the welding process. This particular characteristic sometimes necessitates opting for 304L, with its reduced carbon content, in welding applications to avoid such precipitation and maintain the integrity of the weld.

Features of 301 Stainless Steel Coil

301 stainless steel is a widely used austenitic stainless steel known for its excellent corrosion resistance and high carbon content, enabling versatile cold working to achieve various tempers, including 1/4 hard, 1/2 hard, and full hard conditions. This adaptability makes it ideal for a multitude of applications requiring both formability and tensile strength.

The alloy exhibits remarkable ductility, especially in cold-worked conditions, making it well-suited for numerous welding techniques. It's easily formable and drawable, which, coupled with its high strength and outstanding corrosion resistance, renders it perfect for demanding sectors like aerospace, automotive, and rail.

The low carbon variant, 301L, offers enhanced ductility, ideal for applications needing extensive forming or welding. Overall, 301 stainless steel combines formidable strength with superior corrosion resistance, providing a reliable material solution for advanced engineering and manufacturing projects.

301 Stainless Steel Chemical Composition & Technical Data Sheet

301 Stainless Steel Standards Comparison

| STS | USA | UNS | CHINA | EURONORM | RUSSIA | SWEDISH | JAPANESE | |

| GRADE | AISI/ASTM | NO | GB | NO | NAME | GOST | SS | JIS |

| 301 | 301 | S30100 | 0Cr17Ni7 | 1.4310 | X5CrNi17-7 | 03Х17Н7 | X12CrNi17-7 | SUS 301 |

301 Stainless Steel Chemical Composition

| Grade | Standard | Chemical Composition(%) | |||||||

| C | Si | Mn | P | S | Cr | Ni | N | ||

| 301 | ASTM A240 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.00~18.00 | 6.00~8.00 | ≤0.10 |

301 Stainless Steel Mechanical Properties

| Grade | Conditions | Tensile Test | Hardness Test | ||

| 0.2% Y.S(Mpa) | T.S(Mpa) | Elongation(%)≥ | HRB | ||

| 301 | Annealed | ≥205 | ≥515 | 40 | 95 |

| 1/16 Hard | ≥310 | ≥620 | 40 | - | |

| 1/8 Hard | ≥380 | ≥690 | 40 | - | |

| 1/4 Hard | ≥515 | ≥860 | 25 | - | |

| 1/2 Hard | ≥760 | ≥1035 | 15 (<0.015") 18 (≥0.015") |

- | |

| 3/4 Hard | ≥930 | ≥1205 | 10 (<0.015") 12 (≥0.015") |

- | |

| Full Hard | ≥965 | ≥1275 | 8 (<0.015") 9 (≥0.015") |

- | |

| Super Full Hard | ≥1790 | ≥1860 | 0 | - | |

301 Stainless Steel Finish & Application

Grade 301 stainless steel is utilized extensively in a variety of industrial and commercial applications, where its strength and durability are highly valued. Key uses include:

Rail Car Components: Ideal for structural parts due to its high strength and resistance to corrosion, ensuring longevity and reliability in demanding conditions.

Aircraft Structures: Used in airframe sections where its combination of strength and lightweight properties are crucial.

Trailer Components: Employs its robustness in highway trailers, contributing to structural integrity and longevity.

Automotive Parts: Including wheel covers and wiper blade clips, where its aesthetic appeal and corrosion resistance are beneficial.

Appliance Parts: Utilized in stove element clips and toaster springs, showcasing its resistance to heat and mechanical stress.

Building Materials: Applied in screen frames and curtain walls, offering both structural strength and a polished appearance.

These diverse applications underscore 301 stainless steel's adaptability and performance in environments requiring durability, precision, and aesthetic quality.

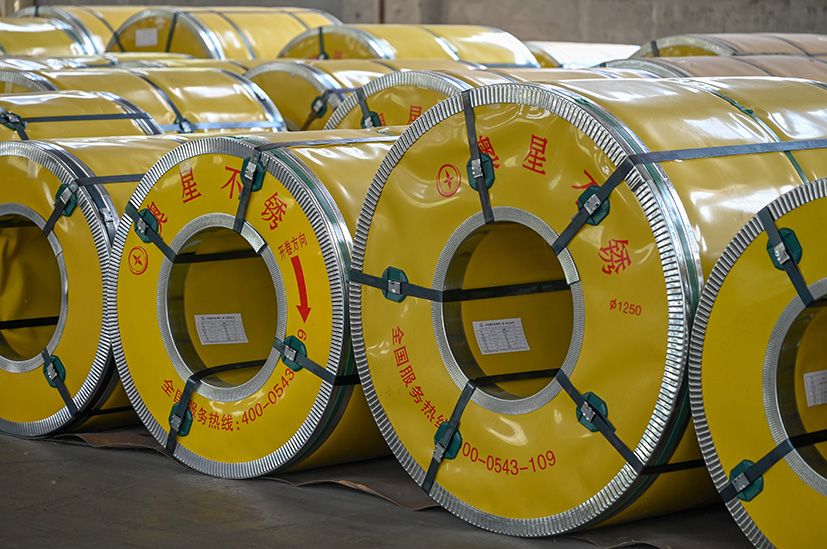

301 Stainless Steel Coil Package & Loading Details

Why Choose Us?

We are the cold-rolled stainless steel coil production base in China with 200,000 tons capacity annually.

1. Guaranteed Stock Availability: Experiencing stock shortages during crucial times can hinder your projects. Our robust inventory management ensures a consistent supply, ready to dispatch large quantities swiftly, keeping your operations smooth and uninterrupted.

2. Comprehensive Range of Specifications: Finding the exact stainless steel coil specifications can be challenging. We offer a diverse range of specs, ensuring you find precisely what your project demands, with the assurance of our commitment to meeting your specific needs.

3. Customized Material Processing: Custom processing needs can be demanding. Our advanced facilities provide tailored solutions, from precise dimension alterations to specific finish treatments, ensuring your requirements are met with utmost precision.

4. Accurate Shearing Services: Precision is key in stainless steel utilization, and our expert shearing services guarantee exactness in every cut, aligning perfectly with your specifications and quality expectations.

5. Cost-effectiveness is crucial in supplier selection. Our optimized procurement and cost-efficient processes ensure you receive not just premium-quality products but also the best prices, offering exceptional value for your investment.

301 Stainless Steel Coil FAQ

1. Can you provide custom 301 stainless steel?

Absolutely, we tailor 301 stainless steel to your needs, ensuring your specifications for thickness, width, and physical properties, hardness(301 1/16 hard, 301 1/8 hard, 301 1/4 hard, 301 1/2 hard, 301 3/4 hard, 301 full hard, 301 super full hard) are met.

2. What's the delivery timeline?

Quick delivery for trial orders within a week, while regular orders range from 7-30 days.

3. How do you guarantee your 301 stainless steel product quality?

Our 301 products undergo rigorous inspections during manufacturing, cutting, and packaging to ensure the highest quality. And 301 mill test certificate is also provided.

4. Can I get some 301 steel samples?

We can provide 301 steel samples for you to check the quality. Sample is free and you just pay the freight.

5. Is 301 stainless steel magnetic?

301 stainless steel is known for its versatility and corrosion resistance, but questions often arise about its magnetic properties. In its annealed state, 301 stainless steel is generally non-magnetic. However, it can become magnetized through cold working processes such as rolling, bending, or shaping. The degree of magnetism induced in 301 stainless steel depends on the extent of cold work and specific conditions under which it is processed.

While 301 stainless steel may acquire some magnetic properties, it's essential to understand that this magnetism is typically much weaker than that of inherently ferromagnetic materials like iron. Despite potential magnetism, 301 maintains its excellent corrosion resistance and other beneficial attributes. For applications where magnetic properties may impact performance, conducting precise tests or consulting with materials specialists is recommended to accurately evaluate the material's behavior in specific scenarios.

6. How to choose a 301 stainless steel supplier?

Selecting a supplier for 301 stainless steel coils involves a series of steps to ensure quality and reliability:

Research Suppliers: Utilize online resources to identify reputable suppliers specializing in stainless steel, focusing on those with a strong industry presence and positive reviews.

Engage with Suppliers: Contact the suppliers to discuss their 301 stainless steel coil offerings, including specifications, pricing, and availability. Consider requesting samples for quality assessment.

Assess Credibility: Evaluate the suppliers' credibility by reviewing their business credentials, certifications, and customer feedback, ensuring they adhere to industry standards and best practices.

Compare Quotations: Solicit and compare quotes from various suppliers, clarifying your specific needs such as quantity, specifications, and delivery details to make an informed decision.

Verify Quality Assurance: Investigate the suppliers' quality control processes and request relevant test reports or certifications to confirm the coils meet your required standards.

Negotiate Terms: Discuss and negotiate key terms, including pricing, delivery, and payment conditions, ensuring they align with your requirements.

Order Placement: Finalize the purchase by confirming the order details, such as the coil specifications, quantities, and agreed terms.

Arrange Payment: Agree on a secure payment method that suits both parties, ensuring all financial terms are clear and documented.

Coordinate Shipping: Organize the logistics, including packaging, shipping, and customs clearance, to ensure the coils are delivered as expected.

Inspect Upon Arrival: Upon receiving the coils, inspect the shipment for quality and accuracy, addressing any discrepancies with the supplier immediately.