When it comes to martensitic stainless steel, the 420 grade is a notable mention known for its hardness and corrosion resistance. This grade gets its hardness from heat treatment processes such as quenching.

Within this family, 420J1 and 420J2 are two prominent grades that achieve their hardness through high-temperature heating followed by quenching in oil or open air. The level of carbon present largely determines the maximum hardness these steels can achieve upon being quenched.

420J1 stainless steel and 420J2 stainless steel are acclaimed for their hardness coupled with excellent resistance to corrosion. 420J2 tends to be harder than 420J1 due to a higher concentration of carbon. The quenching process for these steels is recommended at temperatures ranging from 980-1050℃, and both grades exhibit magnetic properties.

Post heat treatment, 420 stainless steel typically reaches a hardness around HRC52-55. This level of hardness provides adequate performance against damage, which makes these steels a preferred choice for manufacturing knives, thanks to their ease of cutting and polishing capabilities.

Join us as we delve deeper into the world of 420J1 and 420J2 stainless steel and explore what sets them apart.

What is 420J1 Stainless Steel?

420J1 stainless steel, known for its abrasion and corrosion resistance and high hardness, is priced lower than its counterpart. It is ideal for environments that require the standard specifications of stainless steel.

The ability to be hardened through heat treatment makes 420J1 stainless steel (quenching) a versatile choice. Coupled with its corrosion resistance, 420J1 is well-suited for diverse applications.

What is 420J2 Stainless Steel?

420J2 stainless steel stands out as an affordable and exceptionally corrosion-resistant grade. It withstands a variety of conditions, from domestic to industrial, and is resistant to diluted nitric acid.

420J2 stainless steel is standardized under US ASTM specifications, with the everyday standard being SUS420J2, and conforms to the new national standard of 30Cr13.

This grade is particularly noted for its substantial strength and adequate impact resistance when hardened and tempered.

Let’s now compare the performance of these two steel grades in various environments.

If this introduction meets your expectations, I will proceed with the comparison of their performance in different conditions.

420 Material Performance in Various Environments

The 420 stainless steel grade showcases a commendable performance by offering excellent corrosion resistance in diverse environmental conditions. It stands resilient against substances like ammonia, carbonic acid, crude oil, detergent solutions, vinegar, food acids, a variety of petroleum products, and even steam. Both 420J1 and 420J2 are available in hardened and tempered forms, adapting them for use across different temperature ranges.

Strength and Durability of 420J1 Stainless Steel vs. 420J2 Stainless Steel

Tensile Strength:

The tensile strength of 420J2 exceeds that of 420J1 due to its higher carbon content. With superior strength and corrosion resistance, 420J2 stainless steel is often the go-to material for situations that demand these properties.

Hardness:

Post-quenching, 420J2 stainless steel shows a noticeable increase in hardness compared to 420J1 stainless steel. The hardening process involves heating 420J2 steel to 950–1020°C (1742–1868°F) until the temperature is uniform throughout the material.

Yield Strength:

Yield strength signifies the transition from elastic deformation to plastic deformation. Hard metals typically exhibit a higher yield strength. At a 0.2% offset, 420J1 stainless steel has a yield strength of 440 MPa, while 420J2 stainless steel stands higher at 540 MPa.

Chemical Composition of 420J1 Stainless Steel vs. 420J2 Stainless Steel

The chemical composition of 420J1 and 420J2 steels are critical in determining their performance. The carbon content in 420J2 is higher, which contributes to its increased hardness and strength.

| Grade | Carbon C % | Manganese

Mn % |

Phosphorus

P % |

Silicon

Si % |

Sulfur

S % |

Chromium

Cr % |

| 420J1 | 0.16~0.25 | 1.0 max | 0.040 max | 1.0 max | 0.030 max | 12~14 |

| 420J2 | 0.26~0.40 | 1.0 max | 0.040 max | 1.0 max | 0.030 max | 12~14 |

420J1 Stainless Steel vs. 420J2 Stainless Steel – Differences in Weldability

Melting Point:

420J1 and 420J2 stainless steel alloys possess similar melting points due to their comparable compositions, with the primary difference being in their carbon content. The melting points for these alloys range between 2642 and 2750 °F (1450 and 1510 °C).

Weight:

Given that both grades are part of the 420 series and share the same density, 420J1 and 420J2 will have an identical weight for a given volume.

Corrosion Resistance:

Both grades display exceptional corrosion resistance. However, due to its higher carbon content, 420J2 stainless steel may be more susceptible to corrosion in highly humid and saline environments compared to 420J1.

Welding Techniques:

The welding techniques for both 420J1 stainless steel and 420J2 stainless steel are comparable, as they are from the same series. Both grades are known for their weldability, though it’s recommended to avoid welding in annealed, hardened, or tempered conditions to prevent brittleness and cold cracking.

Cost:

While there are minor price differences, 420J2 is slightly more in demand than 420J1 due to its increased carbon content and harder texture. Market values fluctuate, influencing the prices accordingly.

420J1 Stainless Steel vs. 420J2 Stainless Steel’s Weight and Density Comparison

Density of 420J1 Stainless Steel:

The density of a material is calculated based on its mass per unit volume. 420J1 stainless steel has a density of 7.8 g/cm³, which is typical for stainless steels in the 420 series.

Density of 420J2 Stainless Steel:

Since 420J2 and 420J1 are part of the same 420 series, they share approximately the same density value of 7.8 g/cm³.

420J1 Stainless Steel and 420J2 Stainless Steel’s Applications and Industries

420J2 stainless steel is particularly favored for crafting diving knives, common kitchen knives, surgical instruments, hand tools, pump shafts, swords, and daggers due to its hardness and durability.

In contrast, 420J1 stainless steel is commonly utilized in food preparation equipment, kitchen knife blades, industrial machinery blades, mechanical parts, surgical instruments, and in decorative applications where standard corrosion resistance is sufficient.

FAQs

Is 420J2 stainless steel good?

Yes, 420J2 stainless steel is known for its strength, hardness, and corrosion resistance. It is widely used in conditions where hardened and tempered material is required.

Is 420J2 steel good for knives?

420J2 stainless steel is preferred for manufacturing low-cost, durable knives commonly used in kitchens. The grade is also suitable for axe heads due to its hardening capability.

What is the equivalent of 420J2 stainless steel?

AISI 420HC is often considered equivalent to 420J2 due to their similar properties. 420HC is a martensitic stainless steel commonly used for cutlery and other cutting tools.

Conclusion

Belonging to the martensitic family of stainless steels, the 420 grade is further classified into low-carbon types, with 420J1 and 420J2 being prominent examples. The primary distinguishing factor between 420J1 stainless steel and 420J2 stainless steel is the carbon concentration, which influences hardness, strength, and corrosion resistance.

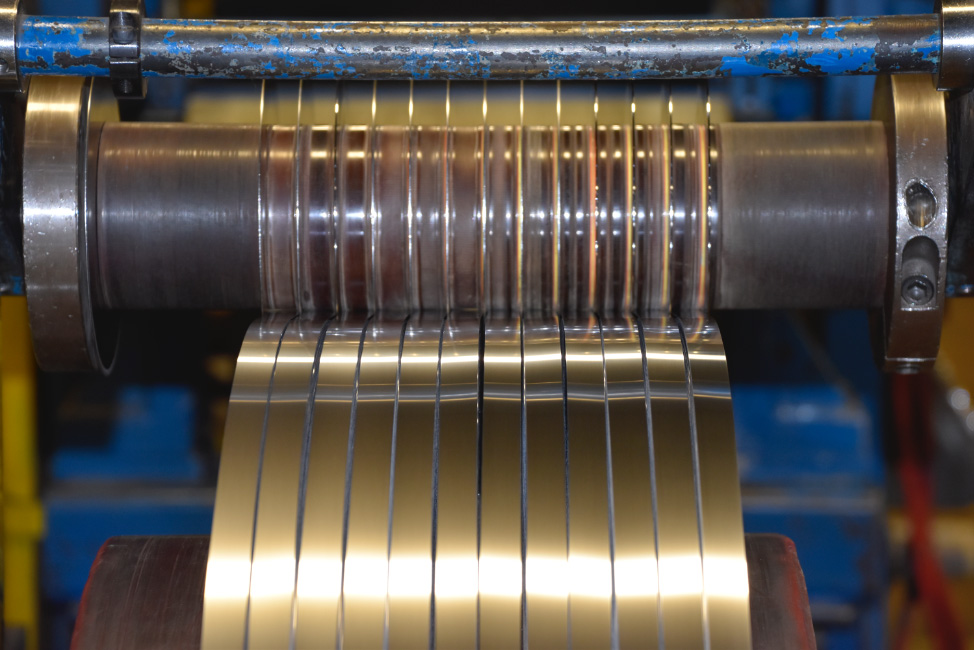

For those seeking expert guidance on selecting the most suitable grade for your 420J2 stainless steel strip project, don’t hesitate to reach out for personalized advice

Post time: Apr-12-2024