420 Stainless Steel Coil

What is 420 Stainless Steel Coil?

420 stainless steel is a martensitic alloy with a higher carbon content compared to 410 and 416, enabling it to be hardened through heat treatment. It boasts at least 12% chromium, ensuring its corrosion resistance capabilities. Primarily distinguished by its ability to achieve high hardness levels of up to 50 RHC, it maintains good ductility when annealed. The optimal corrosion resistance of 420 is attained when it's both hardened and finely polished or ground.

This steel variant demonstrates commendable resistance to various corrosive elements including atmospheric conditions, most foods, freshwater, mild acids and alkalies, steam, and many petrochemicals, provided it's in the hardened state. The elevated carbon content enhances its strength and hardness beyond that of 410 and 416 stainless steels. While 420 machines well in its annealed state, its machinability decreases significantly when hardened beyond 30 HRC. Fabrication techniques must consider its challenging weldability, often necessitating post-fabrication hardening and tempering. It is generally not advised for use at temperatures exceeding its tempering range due to a decrease in mechanical properties.

Feature of 420 Stainless Steel Coil

420 stainless steel is distinguished by its excellent strength, heightened hardness, and superior wear resistance, a direct result of its high carbon composition. While these characteristics make it exceptionally robust, they do lead to reduced ductility and challenging weldability. It offers moderate corrosion resistance, making it the material of choice for applications where mechanical strength is prioritized over resistance to corrosive elements.

The material's physical properties are significantly influenced by any tempering treatments it has undergone, allowing customization to specific application requirements. For precise physical properties tailored to your needs, consultation with our materials specialist is recommended to ensure the suitability of 420 stainless steel for your specific applications.

420 Stainless Steel Chemical Composition & Technical Data Sheet

420 Stainless Steel Standards Comparison

| STS | USA | UNS | CHINA | EURONORM | RUSSIA | SWEDISH | JAPANESE | |

| GRADE | AISI/ASTM | NO | GB | NO | NAME | GOST | SS | JIS |

| 420 | 420 | S42000 | 2100Cr12 | 1.4021 | X20Cr13 | 20Х13 | 2303 | SUS 420J1 |

420 Stainless Steel Chemical Composition

| Grade | Standard | Chemical Composition(%) | ||||||

| C | Si | Mn | P | S | Cr | Ni | ||

| 420 | ASTM A240 | 0.16~0.25 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 12.00~14.00 | ≤0.75 |

420 Stainless Steel Mechanical Properties

| Grade | AISI/ASTM | Tensile Test | Hardness Test | |||

| 0.2% Y.S(Mpa) | T.S(Mpa) | Elongation(%) | Empering Temperature (°C) | HB | ||

| 420 | ASTM A240 | ≥345 | ≥655 | ≥20 | Annealed | 241 Max |

420 Stainless Steel Finish & Application

420 Stainless Steel Applications

420 stainless steel is tailored for applications demanding excellent hardness and good corrosion resistance. It's particularly valued where these attributes are prioritized alongside high strength. The alloy's suitability for use is generally maximized in environments not exceeding 427°C, as higher temperatures can diminish its hardening capacity and corrosion resistance.

This steel is commonly selected for its effectiveness in creating durable and sharp items such as:

1. Cutlery and knife blades, where precision and edge retention are key.

2. Surgical and dental instruments, requiring stringent hygiene standards and durability.

3. Specialty scissors and shear blades, favored for their consistent cutting ability.

4. Needle valves and hand tools, where strength and reliability are necessary.

While 420 stainless steel provides adequate corrosion resistance in mild conditions, it's not the prime choice for severe environments, where materials like 304 or 316 stainless steel, with their higher chromium and nickel content, are generally preferred for their enhanced durability and corrosion resistance. Its mainstay applications are therefore those that leverage its strength and hardness, particularly in the manufacturing of various cutting implements and specialized tools.

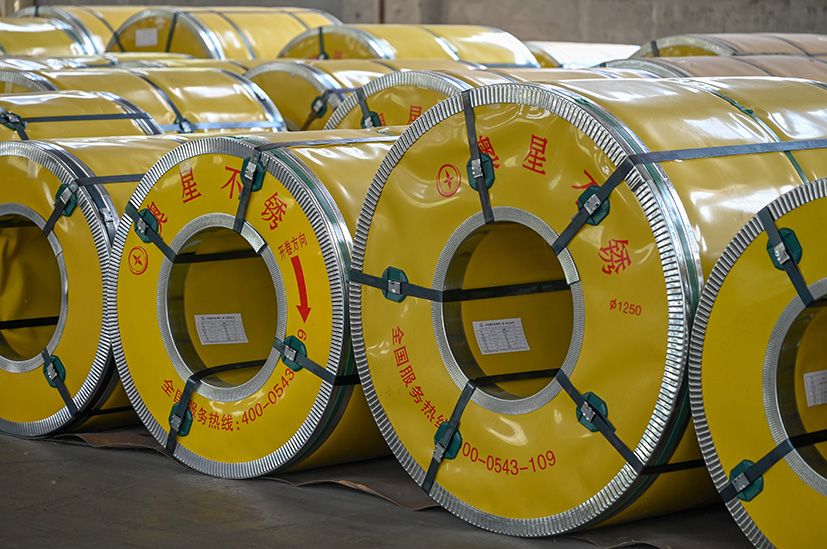

420 Stainless Steel Coil Package & Loading Details

420 Stainless Steel Coil FAQ

1. Can you provide custom 420 stainless steel?

Absolutely, we tailor 420 stainless steel to your needs, ensuring your specifications for hardness(soft, 1/4 hard, 1/2 hard, full hard tempered), thickness, width, and physical properties are met.

2. What's the delivery time?

Quick delivery for trial orders within a week, while regular orders range from 7-30 days.

3. How do you guarantee your 420 SS product quality?

Our 420 products undergo rigorous inspections during manufacturing, cutting, and packaging to ensure the highest quality. And 420 MTC is also provided.

4. Can I get some 420 ss samples?

We can provide 420 ss samples for you to check the quality. Sample is free and you just pay the freight.

5. What is the customizability of 420 stainless steel coil

The adaptability of 420 stainless steel lies in its ability to be tailored through tempering treatments, which significantly affect its physical properties. This customization facilitates the alignment of the steel's characteristics with the specific requirements of your application. To achieve the exact physical properties that you require, engaging with our materials specialist is highly advisable. This ensures that the 420 stainless steel coil is perfectly suited to meet the demands of your particular applications, guaranteeing optimal performance and durability.

6. Is 420 stainless steel magnetic?

Indeed, 420 stainless steel exhibits magnetic properties. Being a martensitic type of stainless steel, it retains its magnetism in both the annealed and hardened states. This inherent characteristic is consistent regardless of the steel's processing or treatment, making it distinctively magnetic among stainless steel variants.

7. What is the ss 420 price per kg?

Usually the approximate price is more than 1,200 US dollars/ton. The actual price will fluctuate based on exchange rates, market conditions, etc. For details, please contact us for a quote.

8. What is the difference between 304 vs 420 stainless steel?

Composition:

420 stainless steel has a higher carbon content (0.15% to 0.40%) than 304 stainless steel, which typically contains no more than 0.08% carbon. This difference gives 420 its notable hardness and strength. However, 304 contains more chromium (18% to 20%) compared to 420's 12% to 14%, providing enhanced corrosion resistance.

Properties:

420 excels in hardness and is preferred for its wear resistance, though it offers less corrosion resistance than 304. Meanwhile, 304 is renowned for its superior corrosion resistance and is better suited for environments prone to acidity or corrosion but lacks the hardness present in 420.

Applications:

The hardness of 420 makes it ideal for cutting tools, surgical instruments, and precision molds. On the other hand, 304 is widely used in food processing, chemical storage, and architectural applications due to its excellent corrosion resistance and adaptability to various environments.

9. Is 420 stainless steel a good choice for making knives?

Yes, 420 stainless steel is highly regarded for crafting knives, particularly favored by chefs, hunters, and divers. Its hardness provides a solid balance of toughness and resistance, suitable for a variety of cutting tasks. A key attribute of 420 stainless steel is its corrosion resistance, which is particularly valuable in damp or marine settings.

It's important to note, however, that 420 stainless steel might not retain its sharpness as well as higher-end steels, but it is notably easy to sharpen. This characteristic, along with its cost-effectiveness, renders 420 stainless steel a practical option for budget-conscious consumers seeking dependable, lower-end knives.

10. How to choose a 420 stainless steel supplier?

Selecting a supplier for 420 stainless steel coils involves a series of steps to ensure quality and reliability:

Research Suppliers: Utilize online resources to identify reputable suppliers specializing in stainless steel, focusing on those with a strong industry presence and positive reviews.

Engage with Suppliers: Contact the suppliers to discuss their 420 stainless steel coil offerings, including specifications, pricing, and availability. Consider requesting samples for quality assessment.

Assess Credibility: Evaluate the suppliers' credibility by reviewing their business credentials, certifications, and customer feedback, ensuring they adhere to industry standards and best practices.

Compare Quotations: Solicit and compare quotes from various suppliers, clarifying your specific needs such as quantity, specifications, and delivery details to make an informed decision.

Verify Quality Assurance: Investigate the suppliers' quality control processes and request relevant test reports or certifications to confirm the coils meet your required standards.

Negotiate Terms: Discuss and negotiate key terms, including pricing, delivery, and payment conditions, ensuring they align with your requirements.

Order Placement: Finalize the purchase by confirming the order details, such as the coil specifications, quantities, and agreed terms.

Arrange Payment: Agree on a secure payment method that suits both parties, ensuring all financial terms are clear and documented.

Coordinate Shipping: Organize the logistics, including packaging, shipping, and customs clearance, to ensure the coils are delivered as expected.

Inspect Upon Arrival: Upon receiving the coils, inspect the shipment for quality and accuracy, addressing any discrepancies with the supplier immediately.

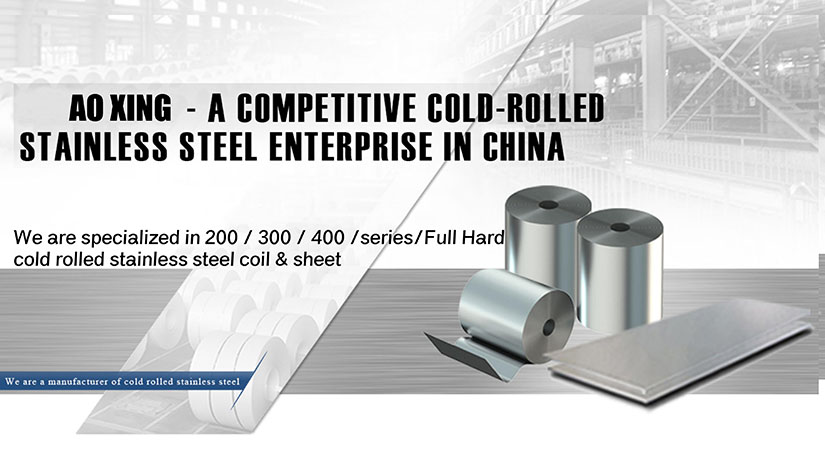

Why Choose Us?

We are the cold-rolled stainless steel coil production base in China with 200,000 tons capacity annually.

1. Guaranteed Stock Availability: Experiencing stock shortages during crucial times can hinder your projects. Our robust inventory management ensures a consistent supply, ready to dispatch large quantities swiftly, keeping your operations smooth and uninterrupted.

2. Comprehensive Range of Specifications: Finding the exact stainless steel coil specifications can be challenging. We offer a diverse range of specs, ensuring you find precisely what your project demands, with the assurance of our commitment to meeting your specific needs.

3. Customized Material Processing: Custom processing needs can be demanding. Our advanced facilities provide tailored solutions, from precise dimension alterations to specific finish treatments, ensuring your requirements are met with utmost precision.

4. Accurate Shearing Services: Precision is key in stainless steel utilization, and our expert shearing services guarantee exactness in every cut, aligning perfectly with your specifications and quality expectations.

5. Cost-effectiveness is crucial in supplier selection. Our optimized procurement and cost-efficient processes ensure you receive not just premium-quality products but also the best prices, offering exceptional value for your investment.